Demineralisation Plant (DM)

Demineralization is a type of water purification. While it can refer to any treatment process that removes minerals from water, the term demineralization is typically reserved specifically for ion exchange (IX) processes used for near total removal of ionic mineral contaminants. Often, the terms demineralization and deionization are used interchangeably. IX demineralization utilizes both cation and anion exchange resins, sometimes even in the same column or bed. After demineralization, the treated water will be of a high level of purity comparable to distilled water, but typically at a much lower cost.

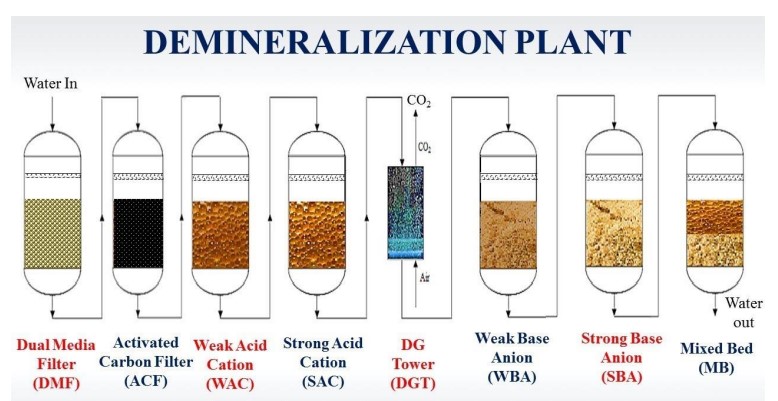

Types of DM Beds

Two-bed IX or dual-bed exchangers use two or more IX resin beds or columns are used to treat a stream, each containing a specific type of IX resin. In two-bed demineralization, a stream is first treated with a strong acid cation (SAC) resin that captures the dissolved cations, and releases hydrogen (H+) ions in exchange. The resulting mineral acid solution is then routed to the strong base anion (SBA) resin bed. This second step sequesters the anionic contaminants while releasing hydroxide (OH–) ions, which combine with the existing hydrogen ions (H+) to form water. The resulting stream is low in TDS and has a nearly neutral pH. While two-bed exchangers are effective for demineralization, sodium leakage can affect the quality of their output, especially for streams with high TDS and/or low pH.

Mixed-bed IX Mixed-bed exchangers offer a higher water quality compared to twin bed systems. Mixed-bed ion exchangers hold a mixture of different IX resins housed within a single IX column. When a stream is introduced to the unit, the cation and anion exchange reactions take place simultaneously within the unit, which has the effect of addressing the sodium leakage issues that can compromise the quality of water produced by a twin-bed IX system. While mixed-bed exchangers produce higher quality water, they also require a more involved resin regeneration process. Additionally, mixed-bed units are more SHARE THIS EBOOK: susceptible to resin fouling and/or inferior system function due to fluctuations in stream contents and are therefore typically used downstream of other treatment measures.

Contaminants removed by DM Process

Cations : The cation resins within a demineralization system will exchange cations, or contaminants having a positive charge.

Common cationic contaminants include:

- Calcium (Ca2+)

- Iron (Fe3+)

- Magnesium (Mg2+)

- Manganese (Mn2+)

- Potassium (K+)

- Sodium (Na+)

Anions : The anion resins within a demineralization system will exchange anions, or contaminants having a negative charge.

Common anionic contaminants include:

- Alkalinity (CO32-, HCO3–)

- Chloride (Cl–)

- Nitrate (NO3–)

- Sulfates (SO42-)

- Silica (SiO2)

Application of DM Water

Demineralization is typically reserved for applications requiring higher levels of water purity, such as feed or makeup water for high pressure boilers, rinse water for food and beverage industries, or process streams used in electronics manufacture

- Power

- Refinery

- Petrochemical and Chemical

- Food and Beverage

- Pharmaceuticals and Cosmetics

- Other industries (chemical production, mining, as well as solvents in applications as diverse as electro coating, research lab)

Chemtech offers a wide range of Demineralization plant based on the client’s specific requirement following all the Pollution Control Board (PCB) norms.. We also undertake annual maintenance contract (AMC), which is not mandatory but advisable for minimizing downtime and maintaining running cost.