Packaged Mineral Water Plant

The processes used in a mineral water bottling plant produce packaged drinking waters that are technically and hygienically pure and backed by several health benefits. To manufacture packaged bottles, manufacturers of mineral water bottling plants use technology that combines both surface and subsurface filtration to treat raw water, convert it to mineral, and then package the finished product in glass bottles. Processes used in a mineral water bottling plant can vary, based on the products and requirements.

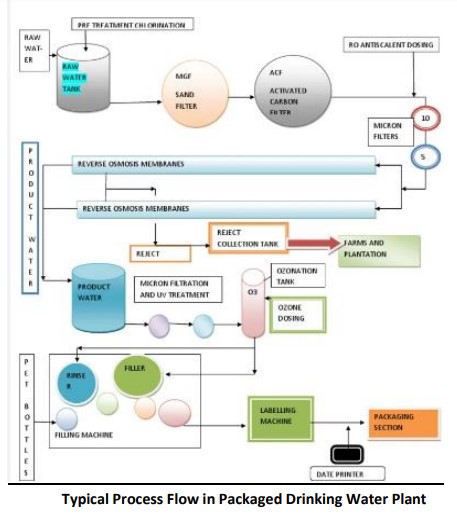

The majority of bottled water businesses use techniques including distillation, reverse osmosis, deionization, filtration, ozonation, or UV light disinfection to treat the water. Companies must use the term “municipal” when bottling water that comes directly from public water supply without any additional treatment.

In addition to the process of filtration, the manufacturers of bottled water must adhere to stricter standards, as set by the government. These guidelines include sanitary conditions, quality standards, and labelling requirements. These regulations vary from state to state, but industry standards are generally more stringent. The government maintains its own set of standards, and all of its members are subject to an annual inspection by an independent third party.

Four Steps of Mineral Processing

- Commination (reduction of particle size),

- Sizing (separation of particle sizes by screening or classification)

- Concentration (using physical and surface chemical characteristics)

- Dewatering (solid/liquid separation).

- Methods of Bottling

Methods of Home Bottling / Canning

- Oven Dry Pack Bottling Method

- Oven Wet Pack Bottling Method

- Slow Water Bath Bottling Method

- Fast Water Bath Bottling Method

- Pressure Bottling Method

Chemtech offer a complete range of packaged drinking water plant from purification to bottling. We chose the methods of purification and packaging depends on the characteristics of the water adhering to the Indian Standards.