Effluent Treatment Plant (ETP)

Chemtech offers a wide range of ETPs over the years. ETP is a process design for treating the industrial waste water. ETP are used by most of the companies in various industries to clean water and remove any toxic and non-toxic materials or chemicals from it so that that water can be reused or released in the environment which will do less harm to the environment.

Need of an ETP

- To clean industry effluent and recycle it for further use.

- To reduce the usage of fresh/potable water in Industries.

- To cut expenditure on water procurement.

- To meet the Standards for emission or discharge of environmental pollutants from various Industries set by the Government and avoid hefty penalties

- To safeguard environment against pollution and contribute in sustainable development.

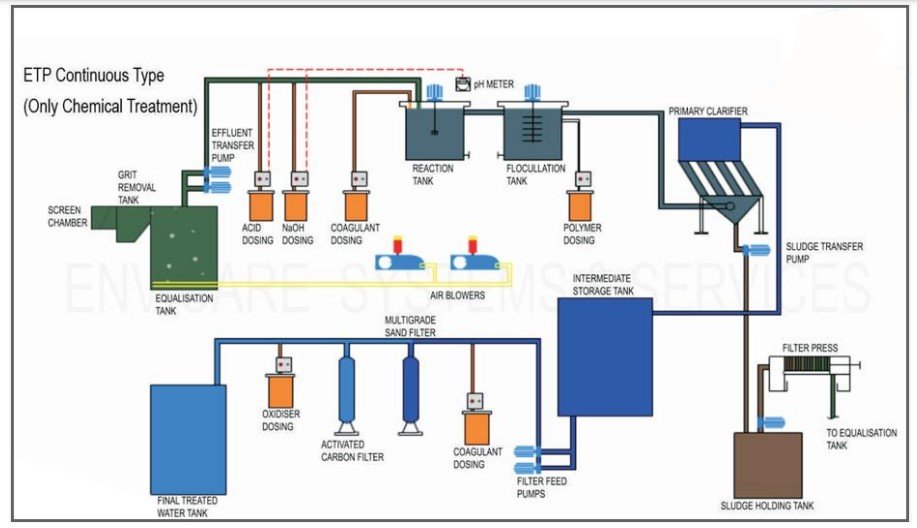

Process in ETPs

Process in ETPs

- Ratio of COD/BOD

- Monitoring of ETP

- Oxidation and Reduction

- Chemical Coagulation and Precipitation

- Settling Treatment

- Segregation

- Thermal Processes

- Activated Carbon

- Stripping

- Disinfection

- Adsorption

- Sewage Tertiary Treatment

- Solid waste disposal, and

- Colour removal

Types of ETPS

Aerobic Reactors

- MBR (Membrane Bio Reactor)

- MBBR(Moving Bed Bio Reactor)

- SAFF(Sub merged Aerated fixed film)

- SBR (Sequencing Bio Reactor)

- FBR (Fludised Aerobic bio Reactors)

Anaerobic Reactors

- Upflow anaerobic sludge blanket (UASBs)

- Expanded granular sludge beds (EGSBs)

- Anaerobic baffled reactors (ABRs)

Depends on the type of industry and its wastewater characteristics, the suitable type of ETPs will be suggested. All the ETPs will be designed, engineered based on the clients requirement in accordance with the norms of Pollution Control Board.(PCB)