Zero Liquid Discharge Plants (ZLD)

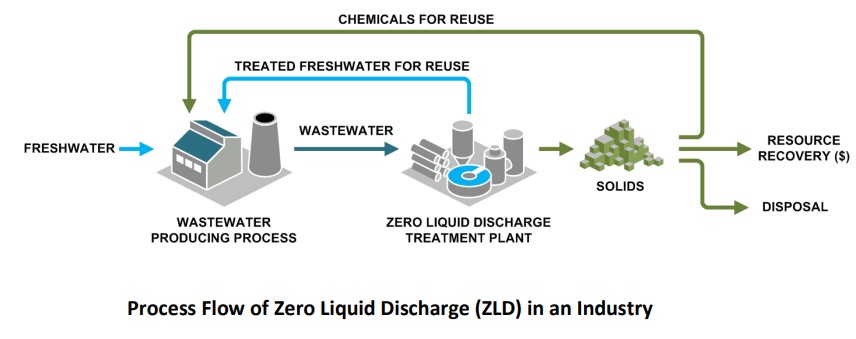

Zero-liquid discharge (ZLD) is a water treatment process in which all wastewater is purified and recycled; therefore, leaving zero discharge at the end of the treatment cycle. Zero liquid discharge is an advanced wastewater treatment method that includes ultrafiltration, reverse osmosis, evaporation/crystallization, and fractional electrodeionization.

Evaporation systems generally are more capital and operating cost intensive than membrane systems, with crystallizers the most costly. For that reason, and when possible, membrane systems can be utilized to reduce the capital and operating cost of the evaporation system.

Depending on the waste water composition, preconcentrating using a membrane system can dramatically reduce the sizing requirement of the backend evaporations system and thus the system capital and operating cost. Note that to reach high recoveries in a waste water membrane system, appropriate pre-treatment such as softening and pH adjustment is often required.

Vertical tubes falling film brine concentrators are generally used to concentrate lower total dissolved solids (TDS) brine solutions up to 12% to as high as 25% total solids and are used to minimize the design capacity of a downstream forced circulation crystallizer. Brine concentrators are specifically designed to manage the scaling of sparingly soluble divalent salts such as calcium sulphate and calcium carbonate, as well as silica that is also commonly present. Forced circulation crystallizers are generally used to concentrate brine blow down from upstream concentration equipment, although small waste water flows are sometimes treated directly with a forced circulation crystallizer. Crystallizers are designed to manage crystallization of all salts, sparingly soluble as well as highly soluble sodium salts such as sodium chloride and sodium sulphate, without excessive scaling and cleaning frequencies. This robustness comes at the expense of higher specific energy consumption and higher specific capital cost.

The solids generated by a forced circulation crystallizer are generally harvested and dewatered by either an indexing belt filter or by centrifuge. In such case the solids are collected and typically landfilled in a conventional landfill as long as the waste passes Toxicity Characteristic Leaching Procedure (TCLP) testing. However, in some applications involving, zero liquid discharge equipment the highly concentrated brine is discharged to an evaporation pond. Such a configuration reduces the footprint of the evaporation pond, and the labor and expense of operating the dewatering equipment.

Applications of ZLD in Industry

- Membrane System Reject (NF, MF, UF, RO)

- Mine Drainage

- Flue Gas Desulfurization (FGD) Blowdown / Purge

- Refinery, Gas to Liquid (GTL), and Coal to Chemical (CTX) Wastewaters

- Produced Water (Conventional, Fracking, SAGD)Scrubber Blowdown

- NOx Injection

- Water Demineralization Waste

- Integrated Gasification Combined Cycle (IGCC) Gray Water

- Landfill Leachate

Chemtech offer a wide range of advanced Zero Liquid Discharge (ZLD) such as thermal evaporators, crystallizers, brine concentrators and spray dryers for wastewater treatment Industries. We design ZLD based on the plant requirement in a cost effective and efficient manner following all the regulations of Pollution Control Board (PCB). We do understand the characteristics and requirement of the plant deeply by testing and analytical study before designing each of the ZLD plant. We do calculate all the aspects of the cost incurring in the installation and operation of the ZLD plant for the optimal reduction of cost.