Softener Plant

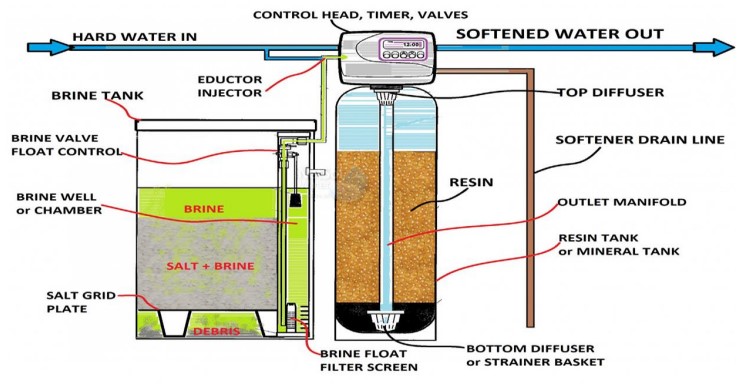

A water softener is a water treatment system consisting of two tanks: a resin tank and a brine tank. The brine tank produces salt, which is carried into the mineral tank to top up the resin bed. When water flows through the resin, hard water minerals are exchanged with sodium (salt). This is known as ion exchange.

Water softeners offer the most effective way to soften water. By removing calcium and magnesium minerals, a water softener should completely eliminate scale and other hard water issues.

Water softeners are solely designed for removing hardness minerals: calcium and magnesium. The ion exchange process also removes low levels of other dissolved minerals and metals, including iron and copper. However, water softening systems can’t remove these minerals completely. Calcium and magnesium are the only minerals that are totally removed by a water softener.

Industrial water softener is a kind of water filter, which removes hardness from water causes due to presence of Calcium and Magnesium. For industries and commercial units, hard water poses a potential threat. The performance of boilers, cooling towers and other associated equipment adversely affected by scaling caused by hard water. Water Softener is considered as concrete solution for this problem, which prevents scale forming. At Bionics Consortium, we deal in industrial hard water treatment with manufacturing of water softener plant from 1 m3/h to 50 m3/h or more.

Our hard water softener systems efficiently remove hardness using the kinetic energy in your water and deliver an uninterrupted supply of softened water all day using unique tank design and certified parts. Our range of commercial and industrial water softeners can also be used for soluble iron removal. In addition to general hard water applications, we supply water softening plant for boiler, heat exchanger and cooling tower of any capacity. We also undertake annual maintenance contract (AMC), which is not mandatory but advisable for minimizing downtime and maintaining running cost. We provide all the solutions and services sticking to the Pollution Control Board (PCB) norms.

Applications of Industrial Water Softener

- Hospitals and healthcare

- Hotels and resorts

- Food processing units

- Cooling tower feed water

- Boiler feed water

- Humidification and air conditioning

- Pharmaceutical industry

- Oil and gas

- Restaurant

- Heating system

Chemtech provides solutions to all your UF needs includes designing, Installation, revamping, AMC and O&M of existing plants adhering to the Pollution Control Board (PCB) Standards.